Blog 2:

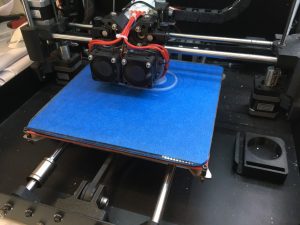

I recently gained access to a 3d printer and a maker space. This type of maker space is usually used by hobbyist and prototypes to create their projects. Here I have the opportunity to use a wood carving CNC machine as well as laser cutter and 3d printer. In the short time that I was there I figured out how to set up level and send prints to the 3d printer using a program called Matter Controller. It was all fairly straight forward and I figured out most of the controls through the menu buttons. The other machines took a little more work and I needed a short tutorial on using the CNC machine to make sure I didn’t harm anything in the process. This was about an hour long and taught me how to turn on set up and run cuts on the CNC. Finally, I spent some time this week trying to teach myself how to topographical carving on the CNC machine, this again was surprisingly easy to learn with a few brief google searches I was able to succeed in carving a mask on the first attempt.

I think what shocked me the most with these projects is just how easily obtainable it was one I had the space to work in. Google and self taught allowed me work out most of the problems and a series of trial and error methods really finalized my knowledge. Now all of the designs I used for printing and carving this week were premade and found on a website known as thingyverse. My next step with this particular project will be to learn how to create my own design to print and or carve as well as learning about the budget that may be needed in order to set up a space similar to the one I am currently working in.

Leave a Reply